THE ULTIMATE LOW-LOSS MULTI-FIBER CONNECTIVITY CHOICE FOR 400G SYSTEM AND BEYOND

MPO connectors are well-suited for high-density, high-traffic applications including data centers and central offices. XFS' proprietary MPO manufacturing process employs the most advanced polishing technology for producing the MPO connectors with the best optical performance in the industry. We can offer 4, 8, 12, 24 and 48-fiber MPO assemblies, with ribbon, flat and round cable structure options. We can also provide MPO assemblies with IP (waterproof) connectivity.

OPTICAL PERFORMANCE

| Item | Parameter | Reference | |

|---|---|---|---|

| Standard 12c SM MPO | Standard 12c MM MPO | ||

| Insertion loss typ. | 0.1dB | 0.05dB | IEC 61300-3-4 |

| Insertion loss max. | 0.25dB | 0.15dB | |

| Return loss | APC: ≥65dB; UPC: ≥50dB | ≥35dB | IEC 61300-3-6 |

Other Suppliers

Use Standard MT Ferrules for Achieving IL max. as

FOR MM MPO

FOR SM MPO

XFS

Uses Standard MT Ferrules for Achieving IL max. as

FOR MM MPO

FOR SM MPO

WITH XFS’ HIGH-PRECISION, PROPRIETARY POLISHING TECHNOLOGY, WE CAN PRODUCE LOW-LOSS MPO WITHOUT USING LOW-LOSS MT FERRULE.

- Charles Sun, CEO

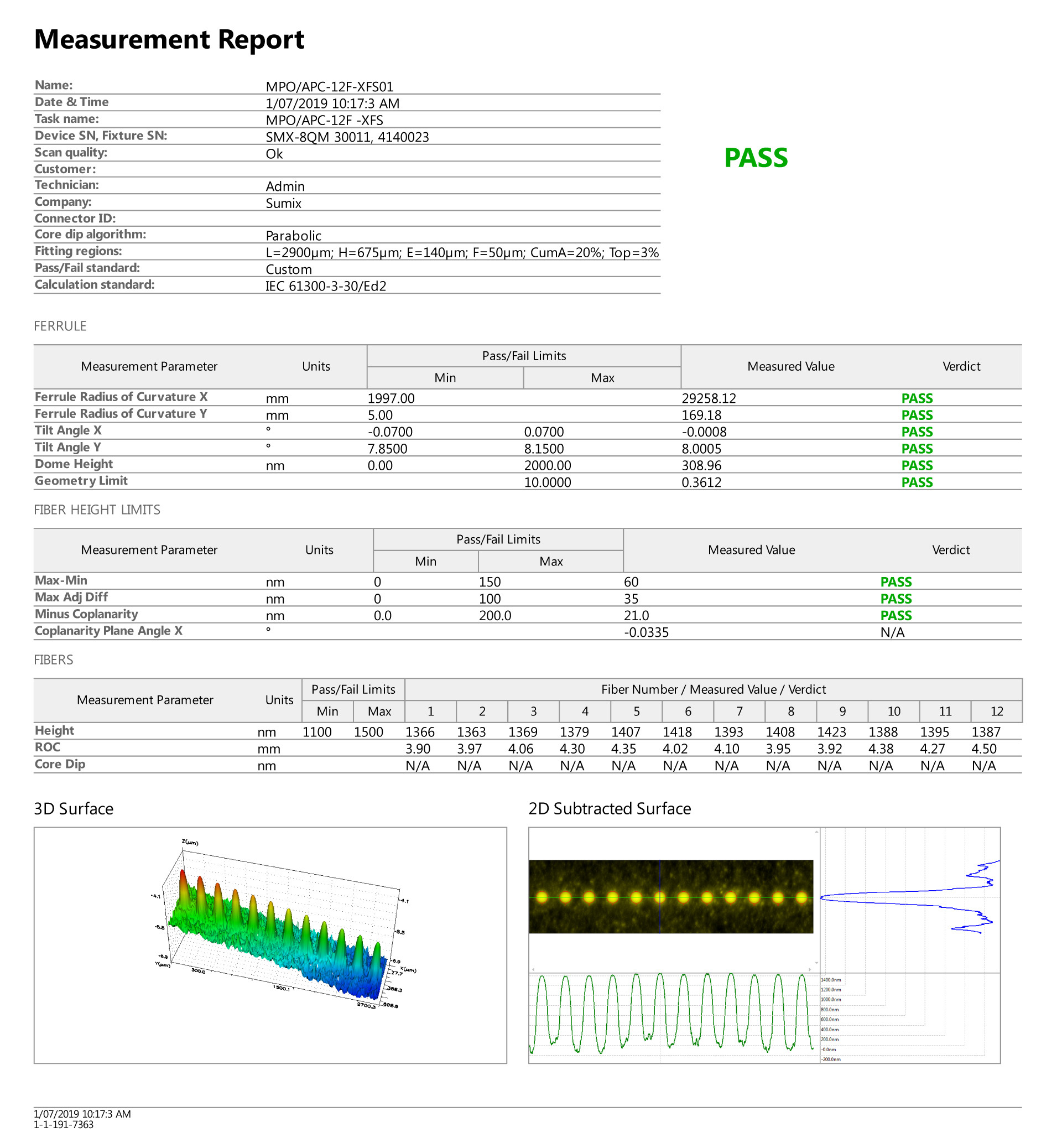

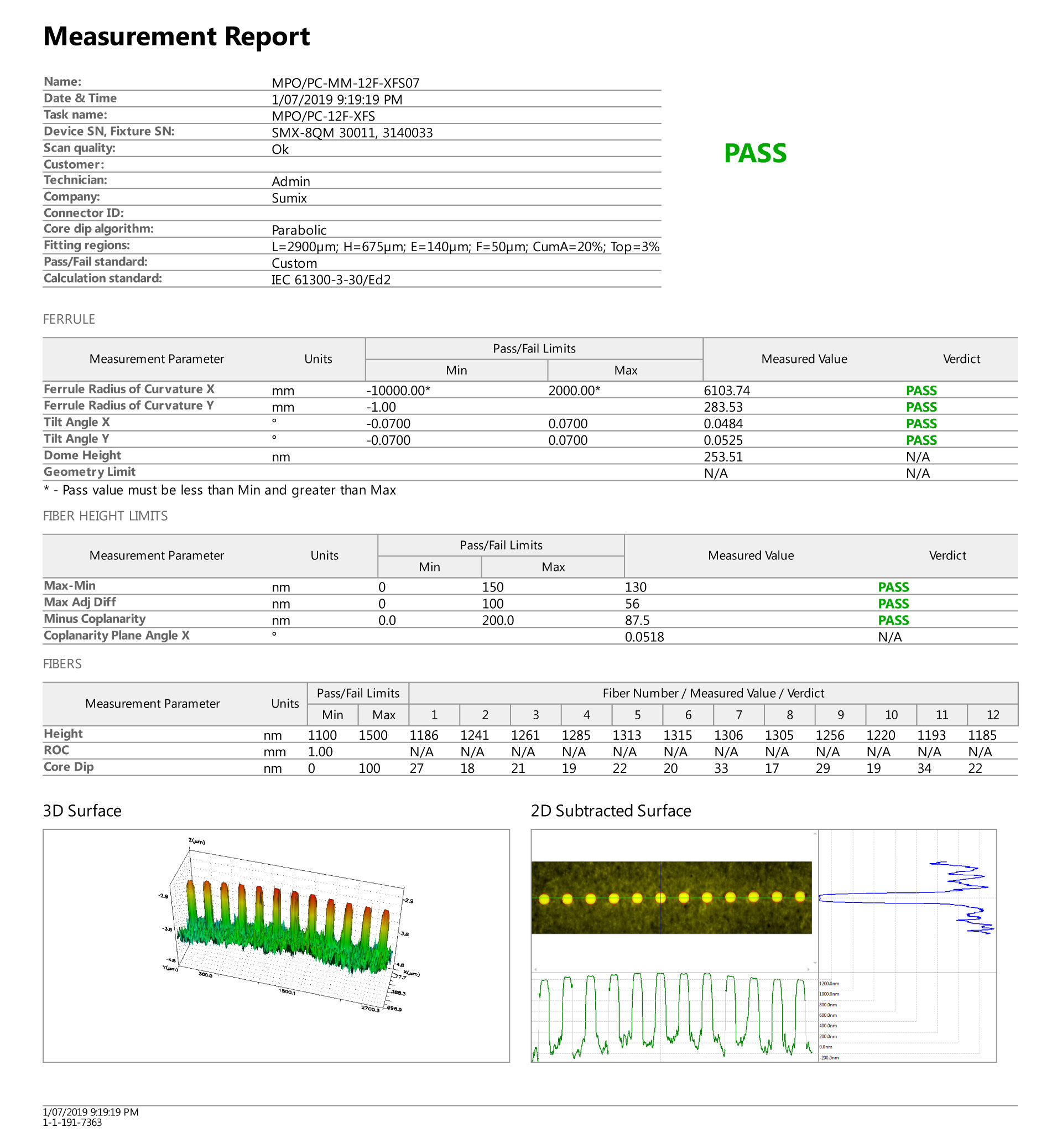

END-FACE GEOMETRY

12c MPO/MTP® Connector

| XFS | IEC 61755-3-31:2015 | |

|---|---|---|

| Minus Coplanarity (nm) | ≤200 | ≤400 |

| Ferrule Surface X-Angle (°) | -0.075 to +0.075 | -0.15 to +0.15 |

| Ferrule Surface Y-Angle (°) (SM) | 7.85 to 8.15 | 7.8 to 8.2 |

| Ferrule Surface Y-Angle (°) (MM) | -0.075 to +0.075 | -0.15 to +0.15 |

| Fiber Height (nm) | 1100 to 1500 | 1000 to 3500 |

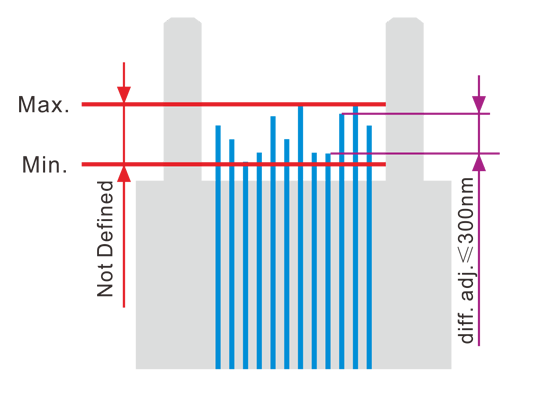

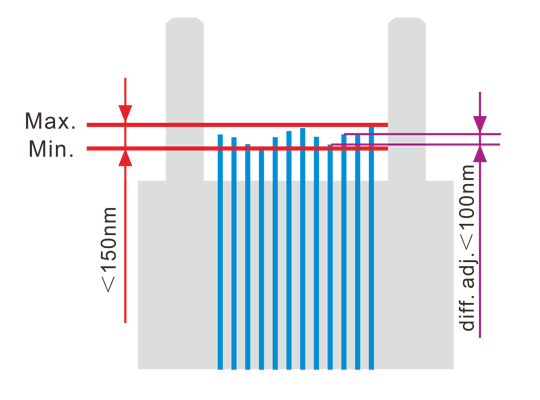

| Fiber Differential Height-All (nm) | ≤150 | Not defined |

| Fiber Differential Height-Adj. (nm) | ≤100 | ≤300 |

| Fiber Tip Spherical Radius (mm) | ≥1 | ≥1 |

| Ferrule Surface X-Radius (mm) | ≥2000 | ≥2000 |

| Ferrule Surface Y-Radius (mm) | ≥50 | ≥5 |

| Core Dip (nm; for MM) | 0 to 100 | Not defined |

| Geometry Limit | ≤10 | ≤17.4 |

FIBER HEIGHT

Fiber Height is a critical factor for connection performance; it needs to be controlled within a certain range, and the distance between the shortest and the longest fiber as well as the variation in adjacent Fiber Heights have to be minimized to ensure good coplanarity of all fibers. XFS has set much tighter tolerances on Fiber Height than IEC to have the most consistent Fiber Heights for a perfect connection.

IEC 61755-3-31:2015

XFS

CORE DIP

Core Dip is major factor in determining insertion loss and return loss of multimode MPO connector. It is a recessed area of a fiber core located at the top of the fiber. Core Dip appears during polishing process because core is usually softer than cladding material and it is easier removed. Core Dip prevents proper physical contact and needs to be minimized. XFS’ MM MPO connector has less than one-third of Core Dip value than industry average.

Other suppliers

XFS

GEOMETRY LIMIT

Geometry Limit can be used to quantitatively assess the acceptability of an MPO’s end-face. This term is a calculated merit function, which relates X-slope angle, coplanarity, and fiber tip radii in comparison to the defined ferrule compression force. For a specific MPO’s end-face condition, lower calculated values for GL indicate a better geometry. XFS has set a far more strict GL than IEC to ensure its MPO connector has the best end-face geometry and optical performance.

IEC 61755-3-31:2015 (12c MPO)

XFS (12c MPO)

END-FACE QUALITY

For end-face quality, IEC guidelines allow a few defects that are small in size. XFS’ fiber optic connector is one of the very few in the industry to deliver connectors with zero defects on the ENTIRE FERRULE END FACE. Thus the connector’s light extraction efficiency is optimized.

| Zone | Range(μm) | XFS (MPO/APC) | IEC 61300-3-35 ed2.0 (APC) | ||

|---|---|---|---|---|---|

| Scratches | Defects | Scratches | Defects | ||

| A: Core | 0 to 25 | None | None | 4 ≤ 3μm | None |

| B: Cladding | 25 to 115 | None | None | No limit | No limit < 2μm 5 from 2μm to 5μm None > 5μm |

| Rest of ferrule | None | None | Not defined | Not defined | |

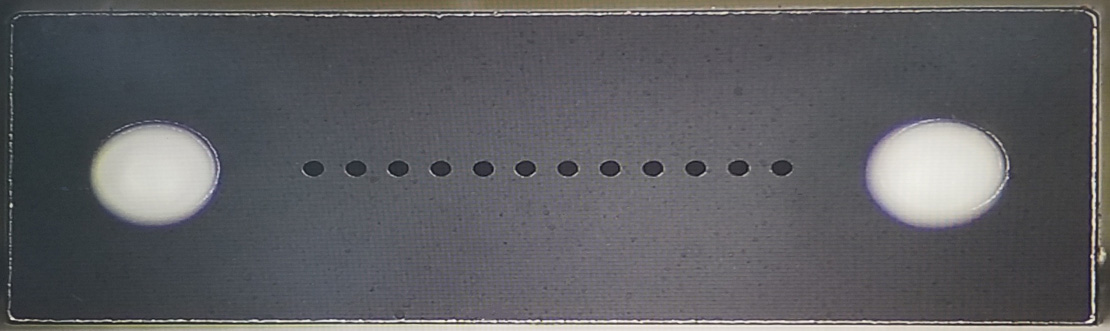

END-FACE GEOMETRY MEASUREMNT REPORT

3rd PARTY SPOT INSPECTION REPORT

‧ MPO-LC Fanouts

‧ LC/APC Jumpers

‧ SC/APC Jumpers

‧ LSH/APC Jumpers

PRODUCT PHOTOS

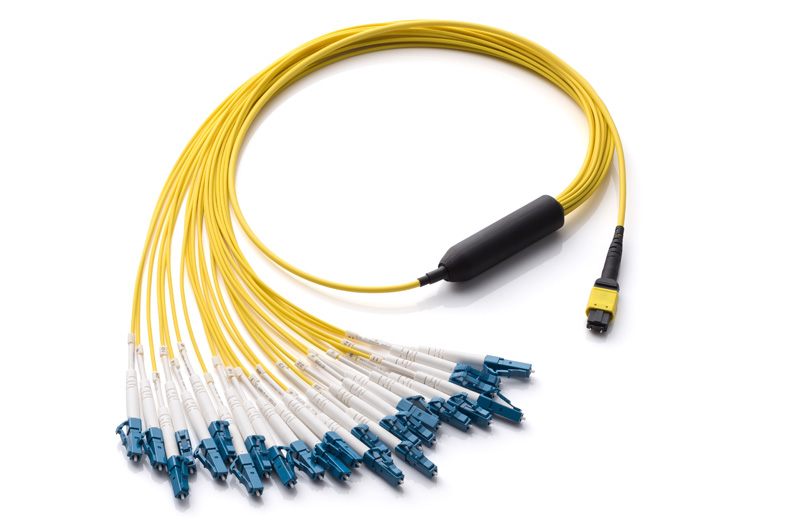

24c MPO/APC-LC/UPC Fanout

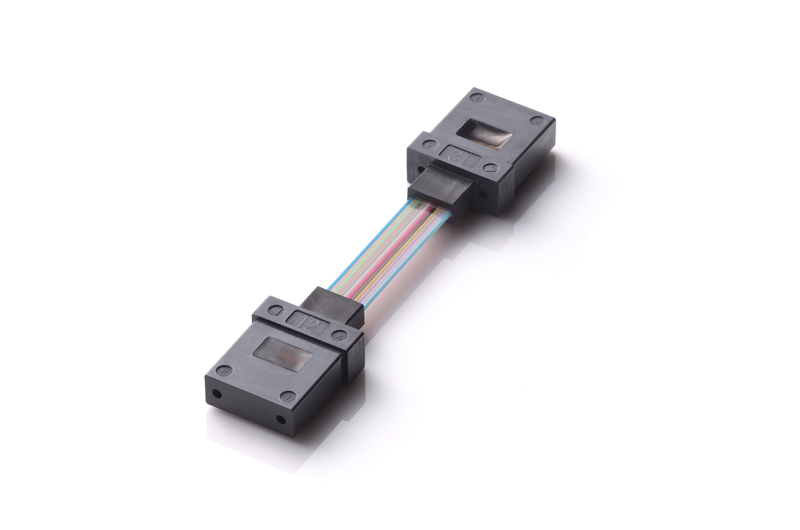

MT-MT Jumper

PRODUCT APPLICATIONS

CENTRAL OFFICE

CENTRAL OFFICE FIBER TO THE BUILDING

FIBER TO THE BUILDING PON

PON DATA CENTER

DATA CENTER FIBER TO THE ANTENNA

FIBER TO THE ANTENNA FIBER TO THE HOME

FIBER TO THE HOME FIBER IN THE HOME

FIBER IN THE HOME CATV

CATV BASE STATION

BASE STATION WAN

WAN LAN

LAN SURVEILLANCE

SURVEILLANCE INDUSTRIAL

INDUSTRIAL HEALTHCARE

HEALTHCARE AUTOMOTIVE

AUTOMOTIVE DEFENSE

DEFENSE